Mold Design & Engineering

Whatever your molding Rubber or Plastic we have you covered. The approach to each mold design is unique to the part and customer requirements. This process is reviewed prior to the start of the design to help eliminate possible problem. We work together with your engineers to help reduce issue that may arise.

Fabricate & Assemble

Some projects require us to fabricate frame enclosure and assemble complete & test before arriving to the customer. This helps streamline project completion dates that are critical. These types of projects rely on strong communication to be successful.

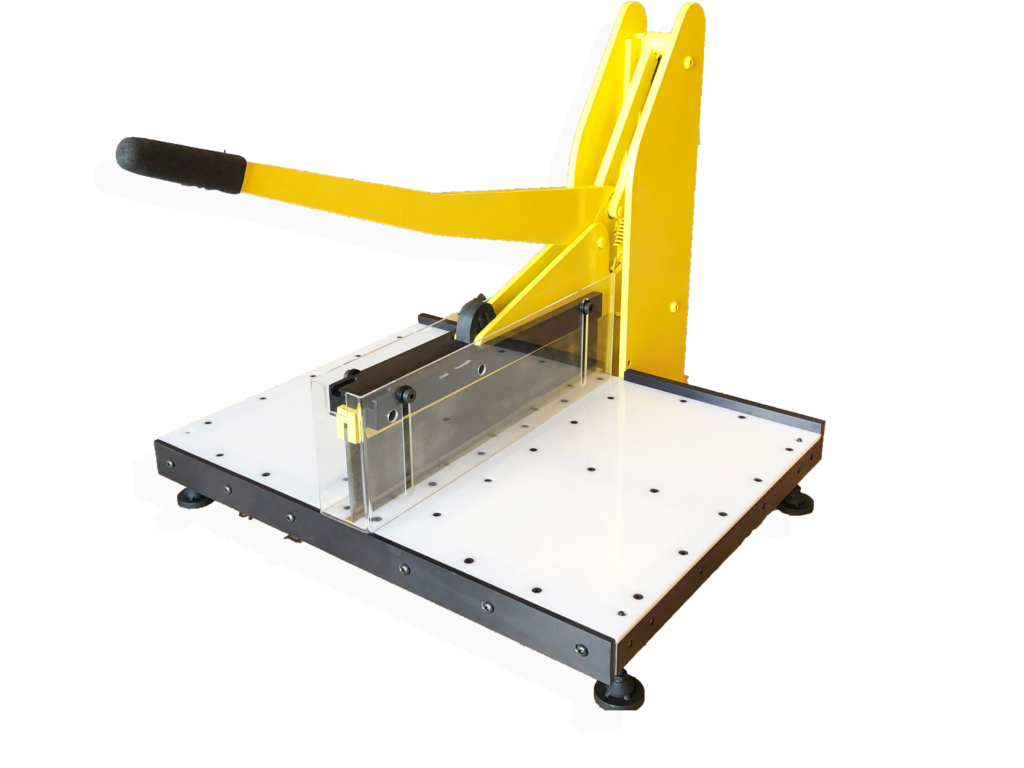

Guillotine Rubber Cutter

The Mechanical Guillotine Rubber Cutter simplifies the cutting process with ease and eliminates the need for mill knives or scissors. Introducing a lighter more simplified design but still has the quality and durability that is expected. The SureCut Rubber Cutter is offered in three blade lengths 6″ , 14″ and 18″(18XL shown above).